SAIGON MECHANICAL TECHNOLOGY

MANUFACTURING COMPANY LIMITED

Aluminum pipe is a commonly used item in projects that require ventilation. You will not find it difficult to see images of them in locations such as kitchens, bathrooms, factories... Although the presence of aluminum tubes is quite common, few people understand this product. To understand information about them, please follow the following article from Saigon Technology.

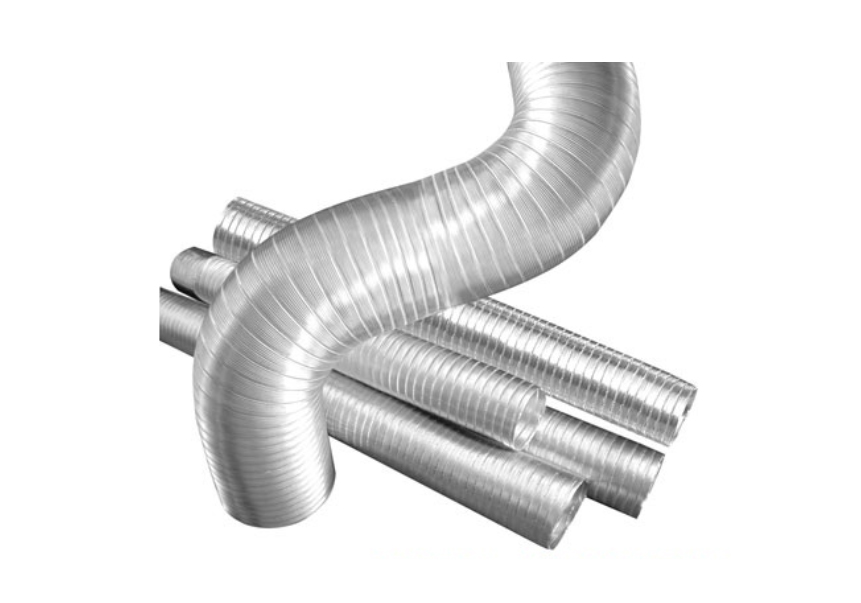

Aluminum spring tube is a closed air duct with elasticity so it can be stretched or folded. The tube is manufactured from many layers of pure aluminum with many folds. Thanks to its malleable nature, embedded aluminum pipes are mainly used for ventilation systems.

Aluminum ventilation pipes today come in many different types and sizes. Popular types include D100 aluminum tube, D150 aluminum tube, D200 aluminum tube,... In addition, you can also see that the product is also classified into heat-insulating aluminum tube, fireproof aluminum tube .

The external structure of the aluminum ventilation duct is similar to the wind corrugated iron duct, but there are still significant differences between them. The tube has outstanding flexibility, elasticity and ability to change shape. This product is made from pure aluminum, helps withstand temperatures up to 600 degrees Celsius and can operate effectively at temperatures of about 250 degrees Celsius.

The surface profile of the aluminum tube is discreet enough to allow it to bend and return to its original shape without damaging the tube, while also preventing air leaks. This product has good flexibility and elasticity, allowing installation in many different spaces and on pipe ends with shapes ranging from round, oval to rectangular.

Industrial aluminum pipes are the perfect choice when traditional PVC pipes or corrugated iron pipes cannot be used. This product is highly appreciated for its applicability, capable of solving problems that other types of pipes cannot solve.

Excellent heat resistance. This product can work well in temperatures up to 250 degrees Celsius.

The product has a discreet structure, with almost no leakage. This helps avoid energy loss, save energy and reduce electricity costs, without affecting the circulation of fluid inside the tube.

With many folds, the product can easily bend and fold while still maintaining quality. This makes it easy to install in many different spaces and replaces pipes with poor elasticity. This can also help save on labor costs.

The product has extremely high durability and is less affected by external environmental factors. Very rarely does damage, deformation, or cracking occur...

In addition, the good aesthetics of aluminum ventilation pipes are also a strong point, allowing direct use in some projects without having to hide through other measures.

In air conditioning systems, boilers and flue systems in places with low and medium pressure, aluminum pipe products often appear widely.

Semi-rigid aluminum pipes, with heat resistance and the ability to absorb dust and smoke, are often used in factories and plants in industrial zones.

Eateries, restaurants and food businesses that need to exhaust odors, smoke or ventilate stoves often use aluminum vent pipes.

This product is also often used to connect exhaust fan systems to ventilation and exhaust systems in factories, kitchens and bathrooms.