SAIGON MECHANICAL TECHNOLOGY

MANUFACTURING COMPANY LIMITED

Different from air duct products used in conventional ventilation and air conditioning systems. EI fireproof air duct is considered a special air duct system. Their specialness is shown in their structure, standards and application systems. Currently, we have been serving fire prevention and ventilation systems for more than 3,000 projects. Our trusted partners: Hoa Binh Corp, FLC Group, Vingroup…

To ensure the safety and effectiveness of the ventilation system, the selection and use of fireproof ducts must comply with Vietnam's technical regulations and safety standards.

Let's join Saigon Technology to learn about EI standards in fire protection and EI fireproof air ducts in the article below:

In regulations on fire and explosion prevention, EI standards are the set of standards regulating the fire resistance limits of fireproof materials. This fire resistance limit is determined in units of time. The fire resistance period of fireproof materials is determined by a fire resistance test under a standard heating regime. During this period of time from the start of the experiment, the temperature was gradually increased from 0 - 1500*C. Until one or more signs appear simultaneously with the limits specified as follows:

Limits on material integrity

E (Integrity) is the limit at which the material structure is maintained perfectly without breaking, falling... without considering the heat transfer ability of the material. This limit is often determined for application in fire protection solutions such as the production of partitions, walls, ventilation systems...

Limits on thermal insulation

I (Thermal Insulation) is the limit at which the material maintains stable thermal insulation ability, the main structure of the material is not damaged by heat effects. Determine this limit to apply to fire prevention solutions such as fireproof walls, fireproof paint, and fireproof limit partitions to ensure fire resistance when a fire occurs. The materials are kept intact, the fire cannot spread, the temperature at the surfaces of the materials is guaranteed.

In the latest standards according to Decree 136 on fire prevention and fighting law QCVN 06:2020/BXD. National technical regulations on fire safety for houses and buildings. The standards of the duct system applied in this new fire protection system have much higher changes. In particular, air ducts and external suction equipment in addition to ensuring TCVN 5687:2010 standards. They must also be made from fireproof materials with fire resistance limits including different EI limits.

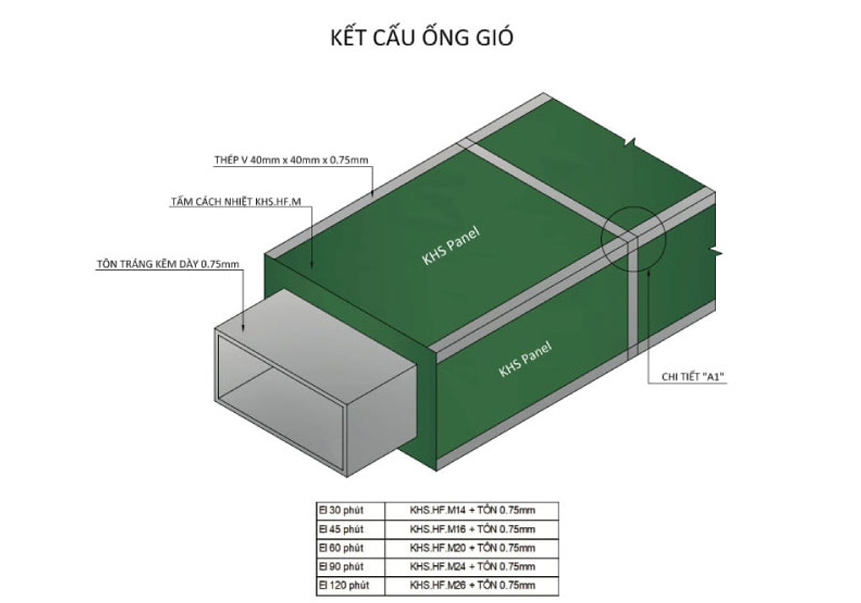

Or to put it more simply, EI fireproof ductwork is a duct system that needs to ensure certain fire resistance limits. Specifically: EI 30; EI 45; EI 60; EI 90 and EI 120, ... Equivalent to fire resistance limits of 30 - 45 - 60 - 90 and 120 minutes.

For each fire resistance limit, air ducts will be structured according to different limits. They need to be within the prescribed limits and tested successfully. And be censored and approved by a functional unit capable of censorship and approval. It should be clearly noted:

+ Requirements for the innermost layer

+ Fireproof class requirements

+ Requirements for the outermost layer, to ensure minimum integrity (E) and insulation (I) according to ISO 6944-1:2008 standards.

+ EI 120: For pipes and smoke channels located outside the scope of the fire compartment that the system serves. Then, at locations where pipes and smoke channels pass through walls and fire compartment floors of fire compartments, normally open fire valves must not be installed.

+ EI 60: For smoke pipes and ducts within the scope of the fire space served, when used to exhaust smoke from enclosed garages

+ EI 45: For vertical smoke pipes and channels within the scope of the served fire compartment; when smoking combustion products directly in that service area

+ EI 30: For other cases within the scope of the fire compartment served.

– No fire resistance limit is required for pipes located in canals and technical wells. If surrounded by fire-stopping components with equivalent fire resistance limits according to regulations.

– Properly arrange exhaust fans with fire resistance limits (for example: 0.5h at 200*C; 0.5h at 300*C; 1h at 300*C; 1h at 400*C; 1h at 600*C or 1.5 hours at 600*C, ...). They must be performed based on the calculated temperature of the moving gas stream. How to correspond to the class of the room being served.

– Smoke and fire products must be discharged outside houses and structures according to one of the following two options:

+ Through the openings, the waste well is located on the outside wall without a door. Not less than 5m from doorways both horizontally and vertically and more than 2m from the ground. The distance to the doorway can be reduced. If ensuring smoke emission velocity is not less than 20m/s.

+ Through separate smoke exhaust wells located on the ground at a distance of not less than 15m. Take into account the exterior walls with doorways and intakes of the air conditioning and pressure boosting systems of that house as well as neighboring houses.

– Allow the exhaust of smoke from smokestacks from the basement through ventilated compartments. In this case, the smoke exhaust must be located at least 6m from the floor of the ventilation compartment. Note (at least 3m vertically and 1m horizontally from the structure of a house) or with wet discharge equipment, it must be at least 3m above the floor. Do not install smoke valves on these pipes.

Above is the most basic information about EI fireproof air ducts. We hope that any customers who are still wondering about this special air duct system. As well as customers who want to buy products. Please contact Saigon Technology Equipment Joint Stock Company. For the fastest quote and support from our consultant team.

Fireproof air ducts at Saigon Technology meet ISO 9001: 2015 standards. Products use Hoa Sen Tole with certified origin and quality. The time to receive the inspection certificate is 7 - 10 days from the time the construction ventilation system is completed. We support nationwide delivery. With two factories (Hanoi, Ho Chi Minh) with an area of over 10,000m2, meeting the large output requirements of all medium and large projects. Besides, we also produce and install cable ladder systems and cable trays for many large projects across the country.