SAIGON MECHANICAL TECHNOLOGY

MANUFACTURING COMPANY LIMITED

Do you know what fiber optic cable trays are? This is an important device in the electrical system, helping to hang and protect electric cables on cable trays. Not only does it ensure the safety of the electrical system, but it also creates a neat and aesthetic layout for the space. In this article, SAIGON TECHNOLOGY will introduce you to the concept, classification and functions of optical cable trays.

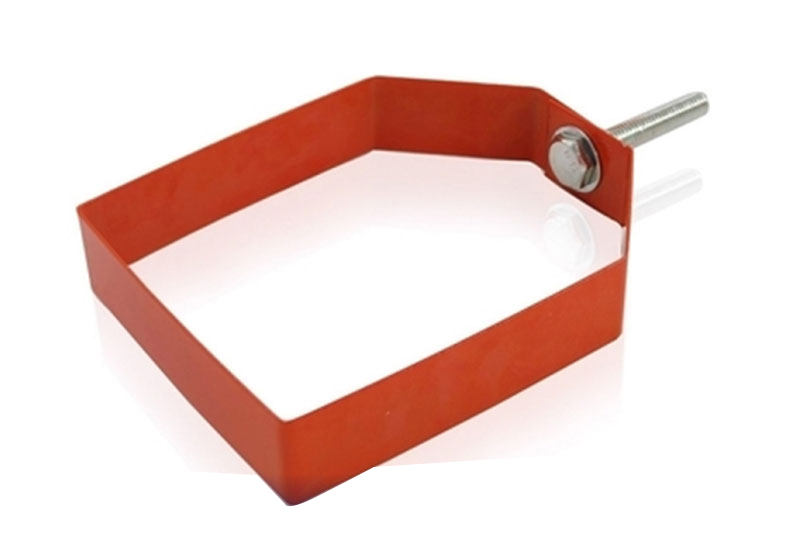

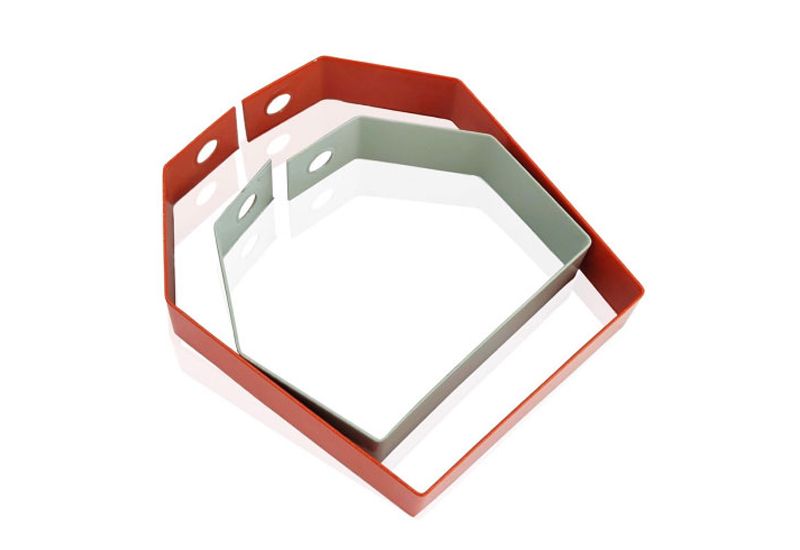

Cable tray hanger is a specialized accessory used to hang and protect electric cables on cable trays. The device has a ladder shape with dimensions suitable for the cable tray and has a punched hole at the top to connect to the threaded rod. The product helps fix the cable tray in the correct position according to the prescribed drawings and creates a neat and aesthetic layout for the space.

With simple and effective features, cable tray hanging belts are used as follows:

Hanging and fixing cable trays, cable ladders or cable trays helps create a safe, stable and durable cable system.

Save on wiring design and installation costs.

Ensure safety and stability of the electrical system.

Suitable for many different types of cable trays

Widely used in telecommunications to connect data centers, cable TV, internet and other applications.

Cable hangers are of great importance in current projects. Cable trays are materials used for heavy and light electrical items. Cable trays help protect wires and cables from external factors such as water, dirt, impact, fire, explosion, etc. Cable trays also help to easily manage, maintain and replace wires and cables when necessary. Cable trays also contribute to creating a control conduction system, ensuring stability and efficiency for the power supply and transmission process.

To have a complete and quality cable tray system, the product is a factor that cannot be ignored. Helps increase safety, stability, save costs and create a beautiful and professional space.

Cable tray hangers can be classified according to the material they are made from. Materials may affect the bearing capacity, corrosion resistance and longevity of the product. Common types of product materials are:

Stainless steel: A type of steel with high chromium content, which helps create a protective anti-corrosion coating for the steel surface. Stainless steel is highly durable, resistant to temperature and chemicals. Stainless steel is also highly aesthetic, does not stain or rust. However, stainless steel has a higher price than other types of steel.

Aluminum: A light, flexible and malleable metal. Aluminum has good corrosion resistance and is not affected by water or atmosphere. Aluminum is also highly aesthetic, available in many different colors and finishes. However, aluminum has lower durability than steel and is easily deformed when impacted or subjected to great force.

Aluminum-magnesium alloy: A type of metal composed of aluminum and magnesium. Aluminum-magnesium alloy combines the advantages of both metals, has high strength, good corrosion resistance and is lighter than steel. Aluminum-magnesium alloys are also highly aesthetic, available in many different colors and finishes. However, aluminum-magnesium alloys have a higher cost than aluminum or steel

Optical hangers cable ladders can be classified according to surface treatment. The surface treatment of the cable tray hanger affects its ability to withstand environmental factors such as temperature, humidity, chemicals, etc. The surface treatment of the device also affects the aesthetics and price of the cable tray. product. Common types of surface treatments are:

Electrostatic coating: A method of using electricity to spray paint on the surface of cable trays. Powder coating comes in many different colors and gloss levels, making the cable tray suspension highly aesthetic. Powder coating also helps cable trays resist corrosion and oxidation in atmospheric environments. However, powder coating cannot withstand high temperatures and can peel off upon impact.

Galvanizing: A method of using zinc solution to coat the surface of cable trays. Galvanizing helps the optical suspension resist corrosion and oxidation in atmospheric and water environments. Galvanizing also helps the optical suspension withstand high temperatures and impacts. However, galvanizing has low aesthetics and can pollute the environment.

Cable tray hanging according to the treated surface will be suitable for different projects. Electrostatic coating equipment is often used for indoor projects that require high aesthetics. Galvanized products are often used for outdoor projects that require resistance

Cable tray hangers can be classified according to size in accordance with the size of the cable tray. The dimensions of this device include width, height and thickness. The width and height of this device usually corresponds to the width and height of the cable tray.

Common sizes of the device are 200x75mm, 200x100mm, 100x100mm, 60x40 mm, 50x50 mm. However, the product may also have other sizes depending on customer requirements.

The thickness of the product can also range from 1.0mm to 2.0mm depending on the material and quality.

Classification by size makes selection and installation easier. With the right size, the cable tray system will be firmly fixed, safe and aesthetically pleasing.

In addition, equipment will also affect the weight and cost of the cable tray system. Therefore, classification by size is an important task in the design and construction of cable tray systems.

SAIGON TECHNOLOGY is committed to providing the best quality products at competitive prices, ensuring safety and quality standards for customers to use. Along with a team of dedicated and experienced staff. Always ready to assist customers in finding and choosing products that suit each customer's needs.